Stoneware glaze firings

- Pottery

- 20 Feb 2021

Below is a record of stoneware glaze firing schedules I have used with my electric kiln.

My kiln controller splits the firing into segements. They consist of

- a heating ramp (°C/h)

- a target temperature (°C)

- a soak period (h.mm)

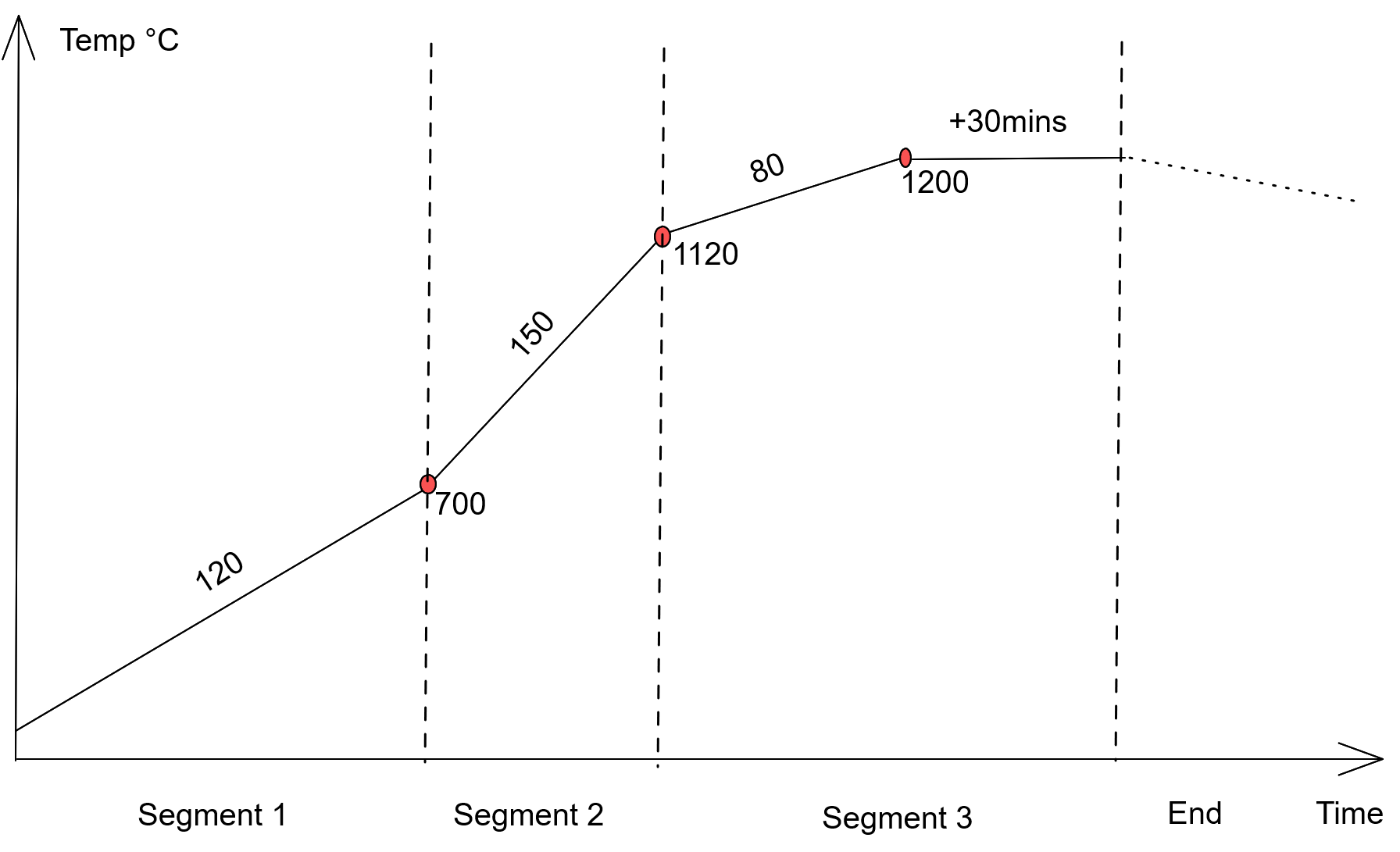

🔥 Normal speed (low)

| Segment 1 | Segment 2 | Segment 3 | ||

|---|---|---|---|---|

| Ramp (°C/h) | 120 | 150 | 80 | End |

| Temp (°C) | 700 | 1120 | 1200 | |

| Soak (h.mm) | 0.00 | 0.00 | 0.30 |

Notes:

- Leave bung in from start to finish

- Open kiln when temperature is below 50°C

- Using a soak to achieve a ‘greener’ firing option in which energy and wear and tear on the kiln is less

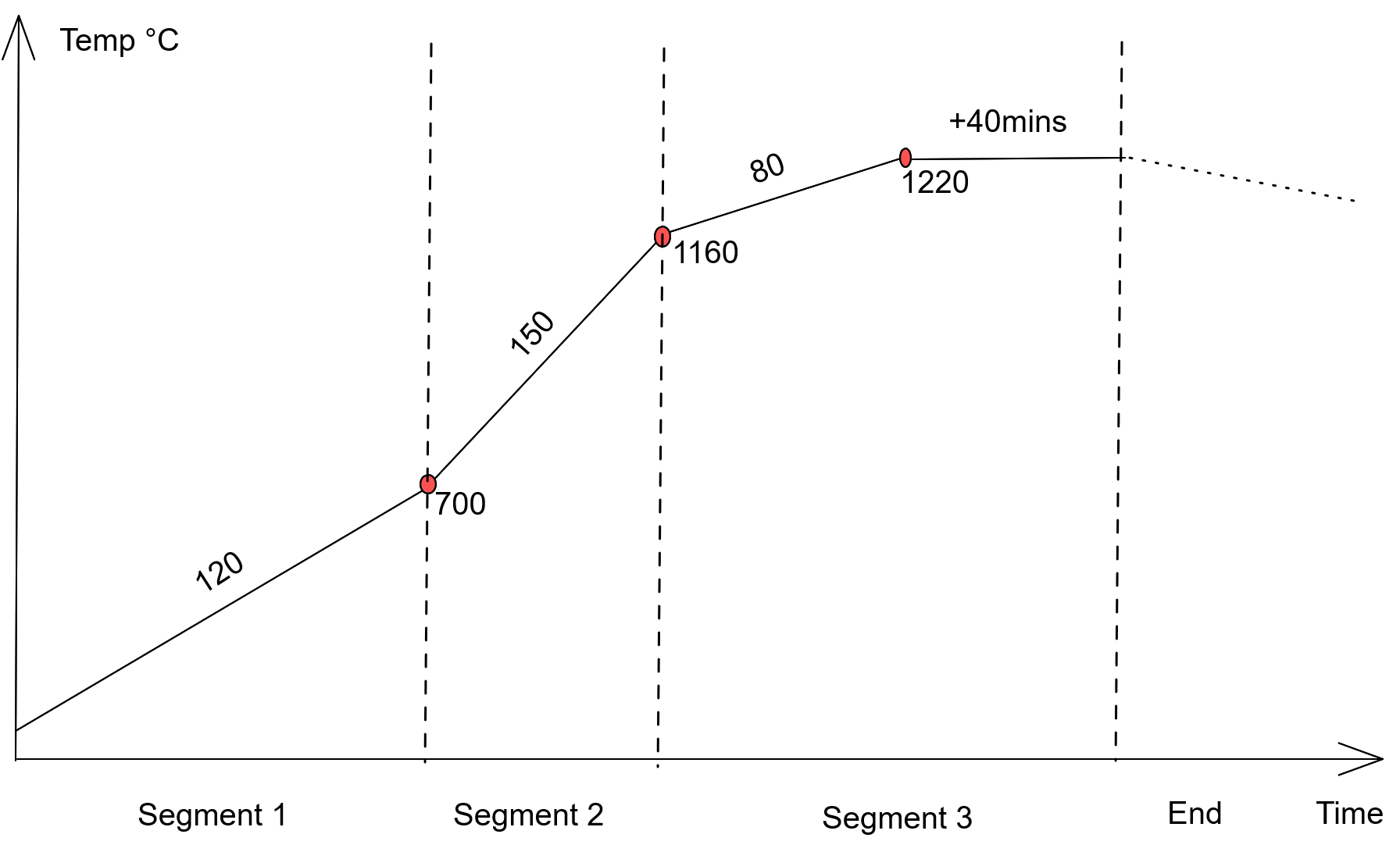

🔥 Normal speed (mid)

| Segment 1 | Segment 2 | Segment 3 | ||

|---|---|---|---|---|

| Ramp (°C/h) | 120 | 150 | 80 | End |

| Temp (°C) | 700 | 1160 | 1220 | |

| Soak (h.mm) | 0.00 | 0.00 | 0.40 |

Notes:

- Leave bung in from start to finish

- Open kiln when temperature is below 50°C

- Using a soak to achieve a ‘greener’ firing option in which energy and wear and tear on the kiln is less

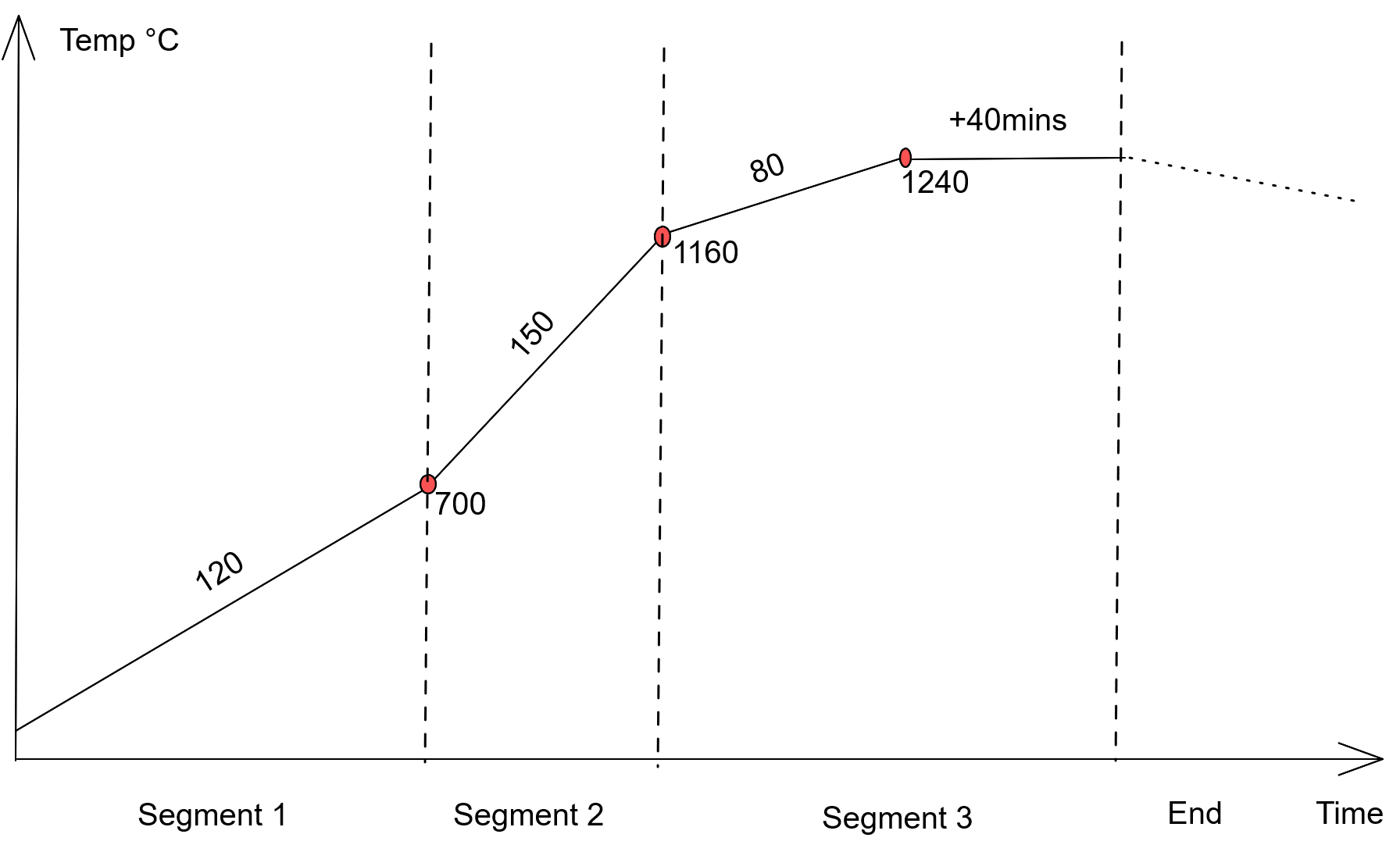

🔥 Normal speed (high)

| Segment 1 | Segment 2 | Segment 3 | ||

|---|---|---|---|---|

| Ramp (°C/h) | 120 | 150 | 80 | End |

| Temp (°C) | 700 | 1160 | 1240 | |

| Soak (h.mm) | 0.00 | 0.00 | 0.40 |

Notes:

- Leave bung in from start to finish

- Open kiln when temperature is below 50°C

- Using a soak to achieve a ‘greener’ firing option in which energy and wear and tear on the kiln is less

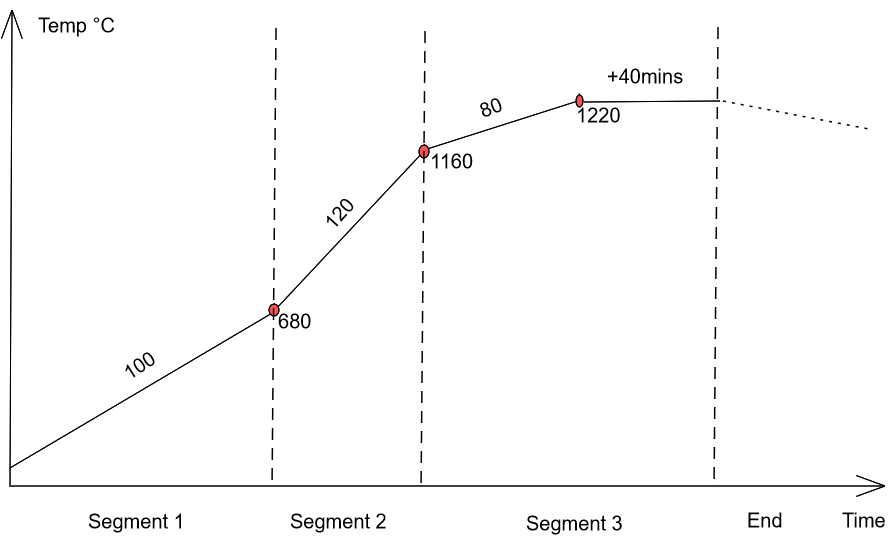

🔥 Slow more cautious

| Segment 1 | Segment 2 | Segment 3 | ||

|---|---|---|---|---|

| Ramp (°C/h) | 100 | 120 | 80 | End |

| Temp (°C) | 680 | 1160 | 1220 | |

| Soak (h.mm) | 0.00 | 0.00 | 0.40 |

Notes:

- Leave bung in from start to finish

- Open kiln when temperature is below 50°C

- Using a soak to achieve a ‘greener’ firing option in which energy and wear and tear on the kiln is less